Since the screws applied in any application have a huge impact on its safety and performance levels, it is critical to select brass machine screws after proper research and assessment. You can explore widest collection of screws and fasteners in the market. But to find the right one for your application, you need to understand the working of the screws. Just in case you could not find the screw for your application from the shop, you can contact custom machine screw manufacturing company that is designing and producing a range of machine screws and providing best custom solutions to their customers.

In this post, experts will talk about major factors that influence the demand of machine screws-

Machine screws manufacturers are producing a range of fasteners without failing in delivering reliable and durable products. With the increment of demand for these products, manufacturing companies are sourcing more raw materials to design brass fasteners and machine screws. Some of the main reasons that explain the significance of machine screws and their usability for applications are listed below-

- Application – Machine screws designed by the engineers are stronger than their counterparts. Users apply machine screws to hold the parts together. Major military equipments, commercial products, industrial machinery, electronic equipment, automotive etc. are fastened by machine screws only.

- Threading – Manufacturers are intending machine screws in distinct sizes and classes as per the application design and model. Manufacturers offering custom machine screws and parts work closely with their clients to develop products that meet all requirements of their applications.

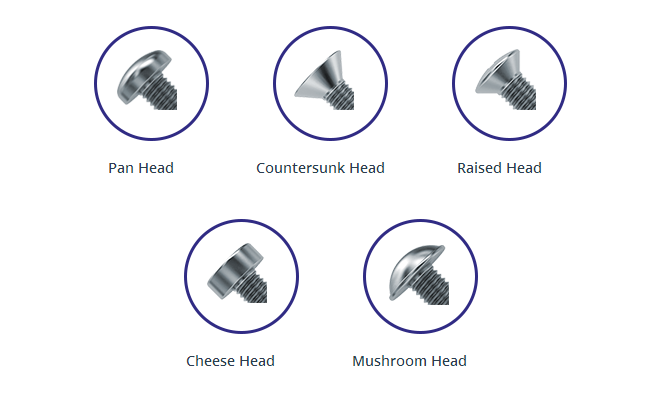

- Screw heads – Screw heads are available in distinct custom shapes, drives, and sizes. Manufacturers are making drives in slotted, socket, Phillips and combo styles. The shapes of the head can be pan, circular, square, flat, etc. The screw design should be selected as per the application specifications and any other components that will be used in conjunction with the application or screw.

- Integrate with threaded holes – Most screws create holes when you drill or push them into an application. Machine screws are designed differently. They can fit into pre-threaded or pre-drilled holes. This feature ensures the strength of the connection.

The quality and app safety relies on the choice of screw. If you fail to pick the right screw for your application, it could trouble you later. For better assistance, you can anytime visit brass machine screws suppliers in your town.