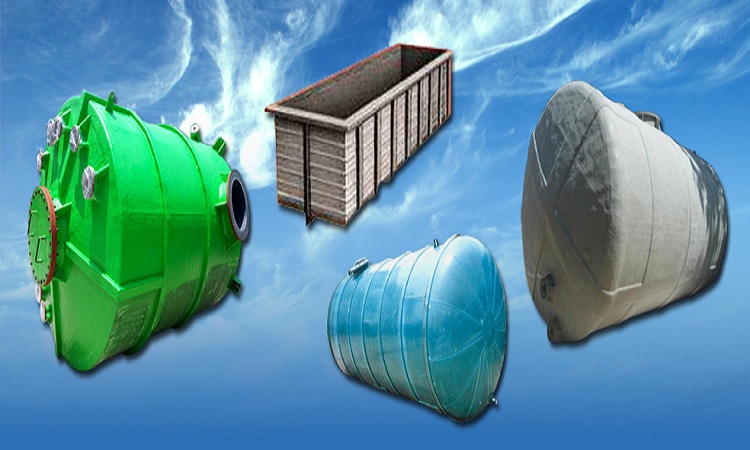

The word FRP in the FRP Tanks refer to the ‘Fibreglass Reinforced Plastic’ material. It is a kind of composite material which is made up of the combination of a polymer material reinforced with fiber-glass. The tanks and vessels which are made up of FRP material are known as FRP tanks. These tanks are generally used in industrial plants as equipment. There are several companies who create and manufacture the FRP tanks and Vessels for various industries and are called FRP Tank Manufacturers. The manufacturers produce the FRP tanks with two main processes – Hand Lay-up and Filament Winding.

The FRP tanks, generally, have a high tensile strength and are resistive to almost everything to protect the material inside it from any chemical reaction. The FRP tanks are manufactured in five major design standards and they are- BS 4994, ASME RTP-1, ASME Section X, SS245:1995, and BS EN 13121. These are the major design standards adopted by various countries to manufacture the FRP tanks and Vessels.

Salient features of FRP Tanks:

The FRP tanks produced by the FRP tank manufacturers have following main features and qualities:

- FRP tanks are well-resistive to corrosion as well as weather conditions. So, the chemical inside the FRP tank cannot be affected by corrosion and weather change.

- The FRP Tanks are highly durable and last for many years (approx. 20 years).

- These tanks have a good conveying capability because of its glossy internal finish and due to which it lowers the pump’s loads.

- These tanks have good abrasion resistance and also have less thermal conductivity.

- These tanks are well-resistive to galvanic and stray electric currents and have a very good thermal insulation property.

- These tanks have a good dimensional stability and adaptability.

- These tanks are generally UV resistant, aesthetically appealing and also have the flexibility in their design.

- These tanks are light in weight and therefore are easy to handle.

- These tanks have an excellent insulating quality.

- These tanks have a high strength to weight ratio which means they are light in weight and thereafter very strong.

- Low maintenance cost is required and therefore it has a very easy maintenance.

- These tanks are quite economical and are also very cost effective.

Applications:

The FRP Tanks are widely used in many applications especially in chemical industry that are developed by FRP tanks manufacturers. These tanks are used in the following sector: chloralkali manufacturer, fertilizer, wood pulp and paper, electroplating, water treatment plant, vinegar, municipal wastewater treatment plant, brine etc. They are also used in storing very strong acids like HCl.