Introduction

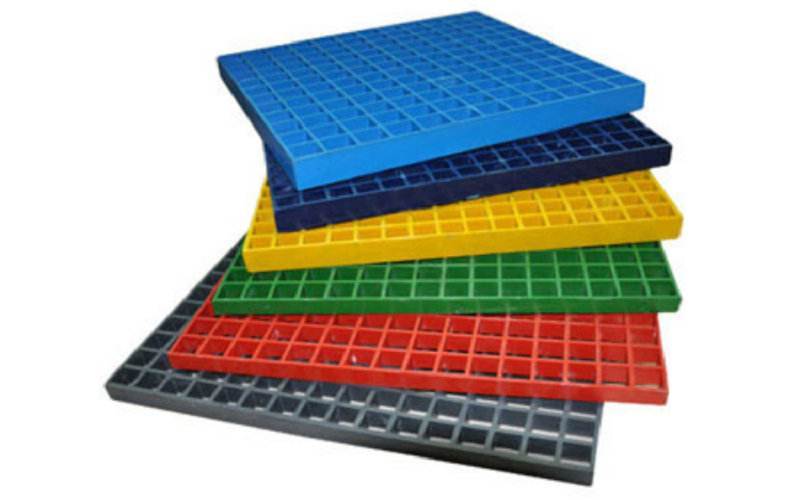

India’s ascent as a global leader in the FRP Gratings Exporters market is a shining example of its capability to merge innovation with cost-effectiveness and strategic market positioning. Fiber Reinforced Plastic (FRP) gratings, which are corrosion-resistant, lightweight, and highly durable, have become the most preferred substitutes for the traditional metals such as steel and aluminum in the industries by chemical processing, marine, oil and gas, and wastewater management.

Indian exporters have thoroughly utilized these merits, using advanced manufacturing, strong supply chains, and a promise of quality to dominate the global market. This article delves into the reasons behind India’s leadership, going into the unique strengths, technological progress, and market strategies of the Indian FRP Gratings Exporters that make them different from the rest.

The Backbone of India’s FRP Grating Supremacy

India’s success as an FRP Gratings Exporters leader result from a trifecta of low prices, skilled labor, and excellent location. These advantages enable Indian businesses to provide high-quality products for prices that keep competitors’ sweat glands active.

Inexpensive Excellence That Pays Off

Indian producers maintain affordability, pricing FRP gratings 20-30% lower than North American or European equivalents. Cheap, however, does not equate to shoddy. Isophthalic polyester is used for its solidity, while vinyl ester is utilized for maximum chemical resistance. Such companies as Aeron Composite and EPP Composites utilize these high-quality resins to construct gratings that shrug off acid spills or salty sea air.

This combination of affordability and resilience allows Indian exporters to supply everyone from cost-saving projects in Africa to high-risk contracts in the Middle East. For instance, one Saudi chemical factory chose Indian gratings instead of more expensive European ones, saving 25% without losing rock-solid performance.

Strategic Geographic Advantage

India’s spot on the map is a major win. Ports like Mundra, Nhava Sheva, and Chennai let FRP Gratings Exporters ship quickly to Asia, the Middle East, Africa, and Europe. Proximity to raw material suppliers in the Asia-Pacific region keeps costs low and supply lines trim. Fibrograts Pvt. Ltd. has the ability to ship gratings to African job sites within less than two weeks, something European rivals are not able to do because of greater shipping expenses. That makes Indian exporters a high priority among last-minute projects such as offshore rigs or sewer plants.

A Workforce That Gets It Done

India’s huge supply of skilled engineers and technicians has played a crucial role in amplifying the FRP grating production. Firms such as Ferrotech India and Bluemoon Fibre Tech implement modern manufacturing methods like pultrusion and open molding that need the technical experts for accuracy and quality. The presence of skilled labor at affordable wages equips Indian manufacturers to channel funds into R&D without an increase in prices, resulting in creative products designed for particular industry requirements.

The Technology That Sets the Standard Higher

Indian FRP Gratings Exporters aren’t playing by the book—they’re making up new rules with leading-edge manufacturing and bespoke solutions that leave old materials in the dust.

Mastery of Pultrusion and Molding

Indian manufacturers are masters of two critical processes: pultrusion and molding. Pultruded gratings, produced by pulling fiberglass through a resin bath and forming it, are ideal for heavy-duty applications such as oil rig platforms. FiberTech Composite produces them in a 65:35 glass-to-resin ratio, which provides strength without excessive weight.

Molded gratings, constructed layer upon layer, provide strength in all directions, and FRP walkways or stairs in chemical plants are ideal applications. Indurotech Composites, in particular, is a company that exploits continuous glass fiber roving strands that are wetted with fire-retardant resins in order to produce molded gratings that are safe for local and global markets.

Personalized Solutions to Each Problem

Tailor-made is where Indian FRP Gratings manufacturers excel best. These types of companies include Aeron Composite and Tribeni Fiber, which provide gratings in various resins—orthophthalic for general work, isophthalic for certain corrosion protection, vinyl ester for severe chemicals, or phenolic for fire-intensive environments. They also modify sizes and surfaces, such as gritty tops to discourage slipping or smooth finishes to enable simpler cleaning.

This versatility allows them to delve into specialized markets, from solar farm paths to wastewater treatment floors. A German chemical factory utilized Aeron Composite’s vinyl ester gratings to fit around challenging pipes, reducing installation time by 20% over steel. That level of customized work keeps Indian exporters in demand.

Going Green with Purpose

The world’s demanding greener materials, and Indian exporters are rising to the challenge. FRP gratings already last longer than steel, reducing replacement and waste. But producers such as Bluemoon Fibre Tech are taking it another step further, experimenting with bio-based resins to reduce the environmental footprint.

An Australian treatment plant for wastewater selected Indian gratings due to their green credentials, which complied with stringent green regulations. This emphasis on sustainability is wooing customers in Europe and North America, where eco-standards are not to be trifled with.

Market Dynamics and Global Demand

The FRP grating industry will reach USD 849.66 million by 2031, driven by the need for light material with corrosion resistance. Indian FRP Gratings Exporters are well placed to take over, supplying large industries and emerging markets.

Powering Big Industries

Chemical plants, marine operations, and oil and gas plants adore FRP gratings for their capacity to withstand vicious conditions. In the Middle East, where oil projects are hot on the burner, Sagar FRP Industries supplied gratings to refinery walkways, saving 35% more on maintenance in comparison to steel. Marine industries employ FRP for gangways and offshore rigs, where it ignores saltwater corrosion. Indian exporters have shipped to Singapore shipyards, offering gratings that endure longer than metal in harsh seas.

Infrastructure Expansion in New Markets

Urbanization in Southeast Asia and Africa is spurring the demand for FRP gratings in wastewater plants, bridges, and industrial floors. Asia-Pacific molded FRP grating market size will reach USD 13,146.44 thousand by 2030, expanding at 4.1% per annum. Indian exporters are taking the lead, providing lightweight gratings that reduce transportation and installation expenses. One Kenyan water treatment plant utilized Indian gratings as acid-resistant flooring, and they saved 15% in project costs since they’re convenient to handle. The trend is extending to Vietnam and Brazil, where there’s construction booming.

Safety That Checks Every Box

Stringent safety regulations globally are increasing the usage of FRP grating, owing to their slip-resistant and non-conductive properties. Indian FRP Gratings Exporters ensure compliance with standards such as ASTM E 84 for fire resistance and BS Part 7 for low smoke. Ferrotech India provides M1-F0 fire-retardant gratings for power plants and offshore installations, gaining confidence in controlled markets such as the EU. Stress on safety creates a bulletproof image.

Competitive Strategies of Indian Exporters

Indian FRP Gratings Exporters don’t simply produce great products—these smart operators play with supply chains, customer service, and digital technologies to lead.

Robust Supply Chain and Export Networks

Strong supply chains are a major contributor to the success of India. Everest Composites Pvt. Ltd. has an intimate relationship with raw material suppliers and logistics allies so that production remains stable and deliveries quick. This allows them to tackle large orders, such as for power stations or refineries, smoothly. Indian trade agreements with ASEAN and Middle East nations reduce export tariffs, making Indian gratings even more competitive.

Customer-Centric Approach and After-Sales Support

Indian exporters bet the farm on customer requirements, providing bespoke solutions and high-quality support. Fibrograts Pvt. Ltd. assists customers in selecting the appropriate grating and provides tips on maintenance to ensure products have a longer lifespan, supporting more than 500 corporate customers spread over 20 states in India and 10 nations. Relationship-building along these lines ensures customer loyalty.

Digital Tools for Global Reach

Online platforms have opened new markets. Vinfab Engineers and EPP Composites use ExportersIndia and TradeIndia to connect with buyers worldwide, showcasing products, certifications, and reviews. Social media campaigns help them break into Africa and Latin America, where demand is growing. This digital push keeps Indian exporters visible.

Challenges and Opportunities

Indian FRP Gratings Exporters have a lot of benefits. However, they are also confronted with challenges that can only be overcome through strategic planning. An insight into their leadership, which is still going on, is provided by the understanding of these challenges and opportunities.

Challenges in Raw Material Availability

Variations in the availability of glass fiber and resin of good quality influence the production costs. The COVID-19 crisis revealed the frailty of the global supply chain. Delays in shipping caused by the pandemic impeded the import of raw materials. Indian manufacturers are solving this problem by increasing the number of suppliers and producing resin locally with the aim of lessening their dependence on imports.

High Initial Costs vs. Long-Term Savings

FRP gratings can cost 1.5 to 2 times more upfront than steel, which turns some buyers off. Indian exporters counter this by highlighting long-term savings—less maintenance, longer life. An Indian wastewater plant saved 50% on maintenance over a decade using FRP gratings, a story that wins over skeptical clients.

Opportunities in Emerging Technologies

New technology is a goldmine. Indian companies are developing gratings that have improved UV resistance, fire protection, and recyclability. Bluemoon Fibre Tech’s environmentally friendly resins have the credentials to satisfy Europe’s stringent green norms, offering Indian exporters a chance at increased market share in environmentally friendly geographies.

Case Studies: Success Stories in the Real World

Indian FRP Gratings Exporters are creating ripples across the world, with projects that exhibit their creativity and reliability.

EPP Composites: UAE Refinery Success

EPP Composites supplied vinyl ester gratings for the platforms of a UAE refinery designed to handle chemical spills and scorching temperatures. The gratings reduced maintenance by 40% over steel, which gave EPP repeat business in the Middle East.

FiberTech Composite: Kenyan Wastewater Win

For a water treatment plant in Kenya that was aimed at dealing with acidic wastewater, FiberTech Composite has supplied pultruded FRP gratings which are also suitable for that purpose. Besides being corrosion-resistant, the lightweight gratings reduced installation time by 30% compared to traditional materials, and their non-conductive properties resulted in the workers being safer. In 2023, FiberTech has completed this project, thus getting the green light to be the major supplier of infrastructure projects all over East Africa.

Aeron Composite: German Precision

Aeron Composite supplied phenolic resin gratings to a German chemical facility, satisfying strict EU fire and smoke regulations. Designed for intricate layouts, the gratings reduced installation complexity and enhanced safety, solidifying Aeron’s European presence.

The Road Ahead for Indian Exporters

With the FRP grating industry projected to expand at 4.5% annually until 2033, Indian FRP Gratings Exporters are poised to dominate the world. New geographies, improved technology, and a commitment to green solutions will keep them ahead.

Entering New Regions

Latin America and Southeast Asia are just waiting to grow. Tribeni Fiber is eyeing Brazil and Vietnam, where infrastructure development requires corrosion-resistant materials. Trade agreements and e-commerce platforms will accelerate this growth.

Tech to Stay Ahead

Automation and intelligent quality control are turning the tables. Indian manufacturers are implementing automated pultrusion lines and IoT to drive efficiency and global demand without compromising.

Green Solutions for a Green Future

With such standards as LEED gaining traction, Indian exporters are creating recyclable gratings and low-emission resins. This green push will help them remain competitive in markets such as Europe, where sustainability is an imperative.

Conclusion

Indian Fiberglass Gratings manufacturers have definitely made a memorable brand in the international market by the help of cost competitiveness, technological innovation, and strategic market positioning. Their capability to manufacture customized gratings of high quality that satisfy the diverse industry needs has made them the only the mainstay of sectors such as chemical processing, marine, and infrastructure.

Indian exporters are now in a very good position to continue their dominance in the world FRP grating market by managing the problems like raw material price fluctuations and high initial costs, by making the best use of the sustainability and new markets opportunities. As industries around the globe are still focusing on durability, safety, and environmental responsibility, India’s FRP Gratings Exporters are well-prepared to fulfill these needs and thus, they will be the driving force of growth and innovation in the near future.

Related Posts:

- Best FRP gratings for walkways

- FRP moulded gratings manufacturing process guide

- Understanding FRP gratings manufacturing process

- FRP gratings non corrosive industrial flooring

- Why FRP pultruded gratings are in high demand

- What is FRP and when should it be used

- How FRP gratings are changing the lifestyle

- Guide to select affordable fiber reinforced plastic fencing

- The various types and advantages of GRP Gratings

- Importance GRP sections construction