In the past five years, India’s manufacturing base has undergone a pronounced preference change, moving from traditional steel gratings toward fiber reinforced plastic (FRP) moulded gratings. Dominant drivers include the ascendancy of sectors such as chemical processing, pharmaceuticals, power generation, and marine infrastructure, where resistance to corrosion, low mass, and overall life cycle economy are paramount criteria. Concurrently, national policies aimed at infrastructure modernisation and sustainability resonate closely with FRP’s engineering and economic characteristics, positioning these products as the de facto standard for operating surfaces such as flooring, walkways, load-bearing platforms, and trench coverings.

What Are FRP Moulded Gratings?

FRP moulded gratings comprise a glass reinforced composite distinguished by the intimate integration of fibreglass matting and high performance somersetting resins. The resulting composite demonstrates heightened specific stiffness and structural integrity, delivered in a non-conductive, non ferromagnetic matrix that effectively decouples itself from the corrosion and electromagnetic performance deficiencies that steel substrates present. Equally significant, the adoption of FRP affords a pronounced reduction in scheduled maintenance frequencies, effectively liberating operating expenditure profiles from the historic burden of corrosion remediation.

Prominent Characteristics of FRP Gratings

- Superior strength relative to weight

- Impressive resistance to corrosion

- Electrical inertia and intrinsic fire retardancy

- Surface engineered for slip deterrence

- Robust ultraviolet and chemical protection

- Farmed Region for Steel Replacement in India

- Resistance to Rust in Aggressive Contexts

Prerequisite steel gratings, regardless of galvanisation, regularly succumb to oxidation in environments typified by harsh chemicals daily environments observed in chemical manufacture, sewage duties, and coastal plantage. Polyster or vinyl ester‐based FRP, by contrast, remains chemically inert and ably resists prolonged sojourns in acidic, alkaline, or saline surroundings, thus becoming the platform of choice for FRP moulded gratings India manufacturers managing continuously harsh processes.

Background for web search: corrosion-resistant gratings, chemical plant flooring, FRP vs steel

- Reduction of Load and Accelerated Assembly

Moulded FRP structures, relative to equivalent steel members of the same load-bearing capability, typically register a weight decline of approximately sixty-seven to seventy‐two percent. Reduced weights cascade into diminished carriage fees post manufacture and into tactical height reductions during assembly. Where plant sections lie at remote and topographically elevated locations one assembly stage, the load diminishes the augmented load and labour cost, diminishes stack load, and diminishes duration to completion during crane disassembly.

- Electrical and Fire Safety

Steel’s inherent conductivity represents a hazard in environments such as electrical substations, battery rooms, and power-generating facilities. In contrast, pultruded fibreglass-reinforced-polymer (FRP) gratings are intentionally formulated to remain non-conductive, thereby reducing incidental electrical exposure. Moreover, proprietary resin chemistries allow FRP to attain fire-retardant properties, complying with both Indian and international ASTM standards for flame spread and smoke density, thus further safeguarding personnel in hazard-prone areas.

- Long-Term Cost Efficiency

FRP gratings typically present a higher capital expenditure when compared to standard mild steel; yet, life-cycle assessment indicates a markedly lower overall economic impact. The material is exempt from periodic painting, galvanising, and rust-inhibiting treatments. Moreover, FRP’s resistance to corrosive environments guarantees an operational life span that eliminates decade-scaled replacement schedules. Surveys among Indian manufacturers now favour analysing total cost of ownership over solely historic initial bid documents.

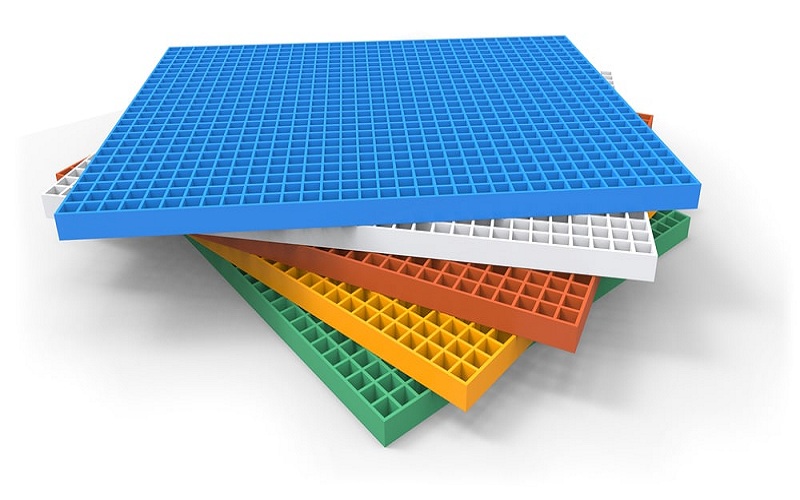

- Customisation and Aesthetic Appeal

FRP gratings are market-conceived in an array of resin pigments, mesh geometries, and surface finishing treatments. This versatility enables project planners to satisfy occupational safety regulations, preserve corporate branding destinies, and target performance-end-use requisites. Anti-slip polymer overlays, thermally fused aggregate grit textures, and plug-in grate modules collectively substantiate FRP as a preferred superstructure for contemporary industrial architecture.

Challenges and Future Outlook

Procurement agencies, still conditioned by entrenched steel frameworks, demonstrate hesitancy in embracing alternative materials. Nevertheless, normative impetus provided by expanded government discourse on smart infrastructure, affiliated “Make in India” directives, and evolving green-building rating schemas collectively signal an impending normative and market inflection point.

Prominent FRP moulded gratings India producers have accordingly pre-emptively developed their product portfolios, now offering gratings that conform to the latest IS standards, complemented by comprehensive value-adding services that shows technical advisory, tailor-made fabrication, and supervised on-site assembly. Such integrated service offerings serve not only to narrow the technical legitimacy gap, but also to translate innovation into scaled industrial application.