Press brake machines are essential for the fabrication of metal or plastic parts into a finished product. Press Brake machines are generally used for bending and shaping sheets of metal in a fast and precise manner while in production, it can be used in either the automotive, aerospace, construction or manufacturing industry for both repeatability and accuracy. The top metal press brake machine manufacturers in India and around the world are working on new designs to provide the newest solutions for today’s manufacturing needs.

What is a Sheet Metal Press Brake Machine?

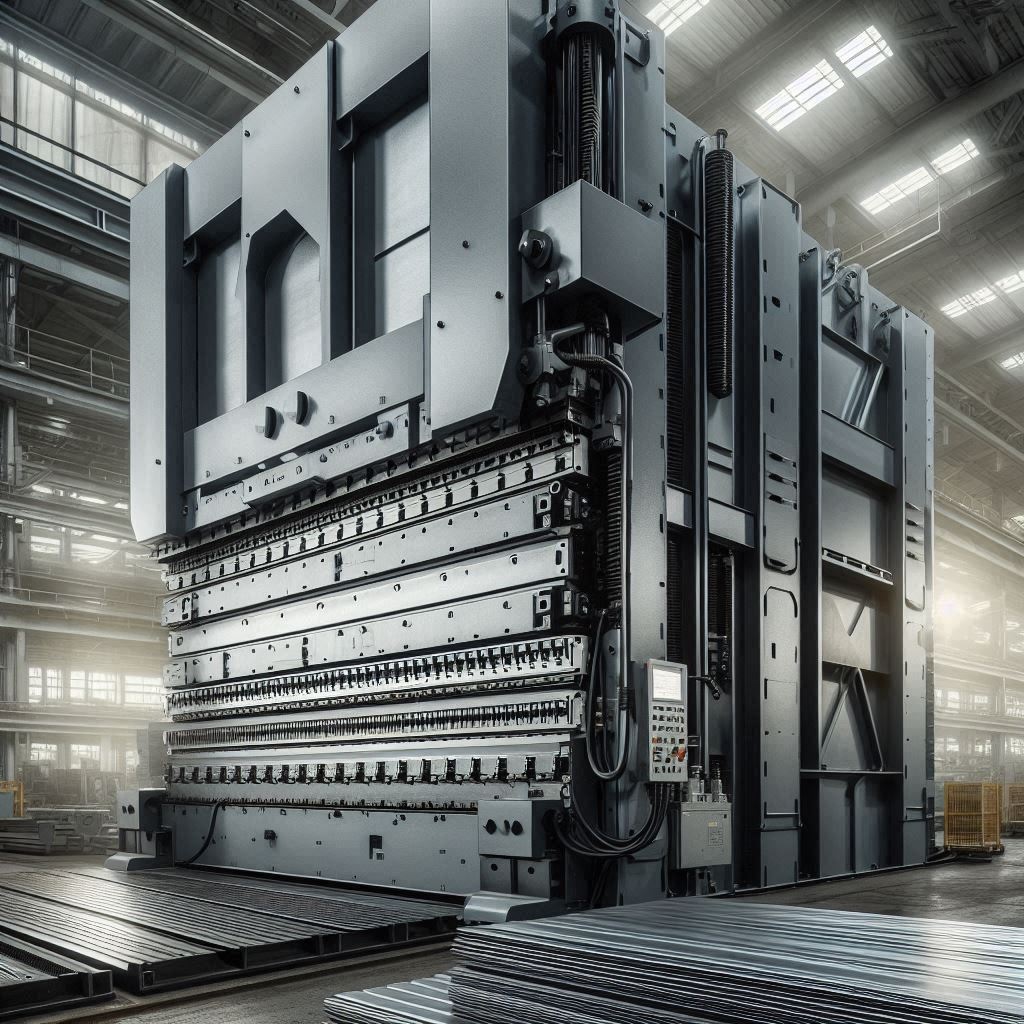

A press brake machine is a type of industrial mechanical machine that operates on hydraulic power for bending metal into different desired shapes. It operates via a punch that pushes down onto the workpiece, which is supported by a die. This press brake tool is a reliable method to achieve precise angles and shapes. Depending on design press brakes will be classified as hydraulic, mechanical, servo-electric, and CNC varying the applications and accuracies.

Types of Press Brake Machines

Various sheet metal press brake machines are available for different production requirements. Hydraulic press brake machines are considered the best option, since they have more power and stability. They are also accurate when bending thicker metal sheets. Mechanical press brakes, powered by a flywheel, are also considered to be too rigid for high-speed production applications. CNC press brakes are automatically controlled by computers, resulting in accurate repetitive bends and complex bends as well. Pneumatic or servo press brakes are very energy-efficient and recommended for light or medium service, where speed and sustainability are the main factors.

Key Features of Modern Press Brake Machines

New sheet metal press brake machines have beneficial features to ensure more precise, safer, and more efficient results. Advanced CNC control systems make it easier to control the angle of bend and back gauge adjustments to achieve better complexity and repetition overall. Hydraulic overload protection keeps the operator safe from running the machine under too much load. High-quality tooling (punches and dies) is supplied by the manufacturer that will last longer and generate a more precise bend.

A programmable back gauge improves productivity and sets the machine up with minimal expense and improved repetition. Modern machines have become more environmentally conscious because they are using technology that incorporates energy-efficient hydraulic systems and energy-efficient drives in order to save the cost energy and environmental impacts, and operate more efficiently.

Advantages of Choosing Reliable Manufacturers

When you partner with a reputable press brake manufacturer, you gain an advantage of a better performing machine, longer-lasting machine, and overall better customer service. Directionally, reputable Sheet metal press brake machine manufacturers build machines from better materials, with precise engineering and high-quality inspection as part of their production quality control to ensure their machines operate consistently and perform consistently.

Also, trusted manufacturers will have ability to develop a custom built press brake to meet your specifications, and will provide customer service after sale, as well as operator training to support getting the most out of your press brake.

Applications of Press Brake Machines

Press brake machines serve a variety of industries when forming and fabricating metal parts including brackets, enclosures, panels, frames, and structural components. In automotive body fabrication, appliance manufacturing, shipbuilding, and industrial equipment fabrication, press brake machines are crucial because of strict repeatability and tolerance requirements.

How to Choose the Right Manufacturer

There are a number of important things you should consider in assessing a sheet metal press brake machine manufacturer to assure enduring quality and performance. Start by examining the manufacturer’s history in the metal forming industry and their reputation and experience therein, because reputable experience often translates to trustworthy and accurate work. Manufacturers that offer CNC or hybrid models are typically more effective and enhance control. Always confirm that the manufacturer has ISO or like certification to assure that they are qualified to work to international manufacturing standards. After sales support and service with a competent staff for maintenance and spare parts is a very important consideration too! Finally, always select a manufacturer that offers customization possibilities to ensure the machine alignment with your production needs.

Conclusion

Sheet metal press brake machine demand is increasing rapidly due to automation and precision engineering in manufacturing. By choosing a reputable press brake manufacturer in India or anywhere in the world, you can ensure that your press brake is built to last and is a solid and efficient machine, designed with the specific needs of the consumer in mind. With improvements in CNC control and hydraulic designs, presses have become more energy efficient while still achieving quality performance, so the next generation of press brake machines in exist with the right combination of performance, accuracy, and reliability, allowing industries to produce excellence in every bend.