Machined investment casting has emerged as a keystone in modern-day manufacturing to provide high precision metal components for strong, durable and accurate industries. India, with its burgeoning manufacturing capabilities, has become a global provider of machined investment castings that meet international quality standards, while also being an economically viable option.

What Is Machined Investment Casting?

Investment casting, usually referred to as lost-wax casting, is the process of using wax to create an investment with a ceramic material. Wax is first coated in the ceramic material and allowed to harden. Once the investment is hardened, it is heated and the wax is melted away. The wax is then replaced with molten metal that makes contact with the ceramic cavity, creating the part. Machined investment casting takes the process to a further extent because the cast parts are precision machined to tight tolerances, smooth finishes, and the end-application dimensions required for a high-performance application. This process combination provides superior strength, consistency, and dimensional accuracy.

Applications of Machined Investment Casting

All levels of industry use machined investment castings for parts that require complex shapes, high tolerances, and high durability. Investment castings are used for automotive applications in multiple parts such as engine components, turbochargers, transmission cases and suspension components. Investment castings are used for aerospace & defense applications in multiple parts such as aircraft engines, landing gear components, and structural components, which must maintain a high strength-to-weight ratio. For industrial equipment, investment castings can be used for pump housings, valves, hydraulic and other connections, and various other commercial machinery parts.

In the energy field, we see machined investment castings in turbines or critical components in power plants and oil & gas equipment. In medical devices, we see machined investment castings in surgical instruments and other specialized equipment that require tolerances. Machined investment castings have a broad usefulness in many high-performance industries.

Advantages of Machined Investment Casting

Opting for machined investment casting presents various benefits for manufacturers wanting precision and efficiency. Precision is ensured because machining after casting yields exact dimensions and tight tolerances. The casting process also supports complex shapes and can create a variety of intricate geometries that are difficult to create with other traditional casting procedures. Machined Investment Casting also offers excellent material versatility as it can use steel, stainless steel, aluminum, titanium, and other specialized alloys. Machined investment casting also presents a favourable solution for cost-effectiveness because it reduces the amount of wasted material, and leads to less secondary operations. The final surface finish of machining benefits from smoothness, which enhances the performance of the component and would support the demands of a high industrial application.

Why India Is a Preferred Destination

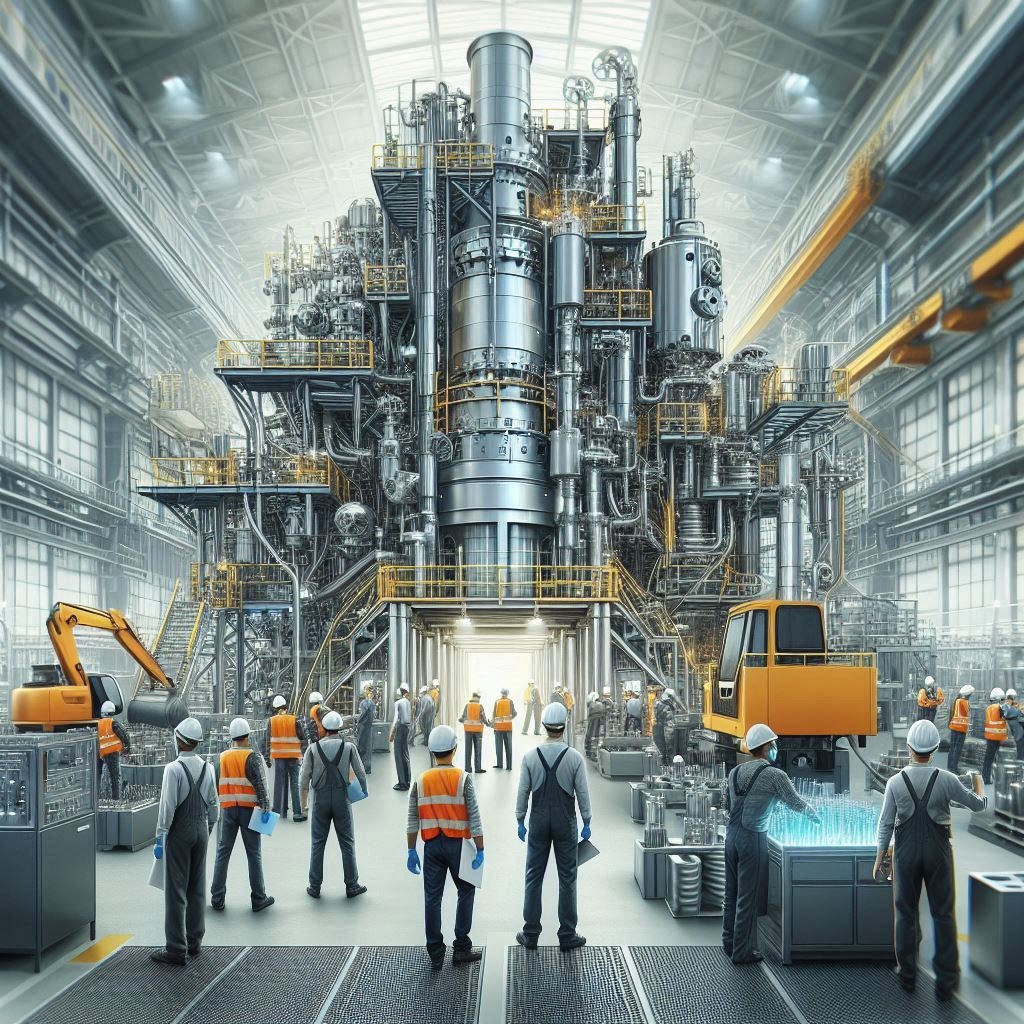

India has emerged as a premier place for machined investment castings because of the unique combination of expertise, infrastructure and price. India has a large, and experienced workforce of engineers and technicians who work in the casting and precision machining business. India has an advanced infrastructure of modern foundries, CNC Machines and quality testing equipment to consistently produce high-quality components. Indian manufacturers conform to international standards like ISO and ASTM that provide customers with reliable, certified products. Even with competitive cost structures, Indian manufacturers can compete with export strengths with customers in the USA, Europe, Middle east, and Asia. All of these strengths provide global industries the best value for precision and efficiency in machined investment castings.

Conclusion

Machined investment casting India merges the versatility of investment casting with the accuracy of CNC machining to provide parts that are durable, precise, and consistent. With India’s emerging expertise and growing capabilities, global players have now access to machined castings at competitive pricing. From automotive, aerospace, energy, or industrial applications, Indian manufacturers offer machined castings that can meet the highest standards of the international community. Therefore, they are becoming partners of choice in the modern manufacturing environment.