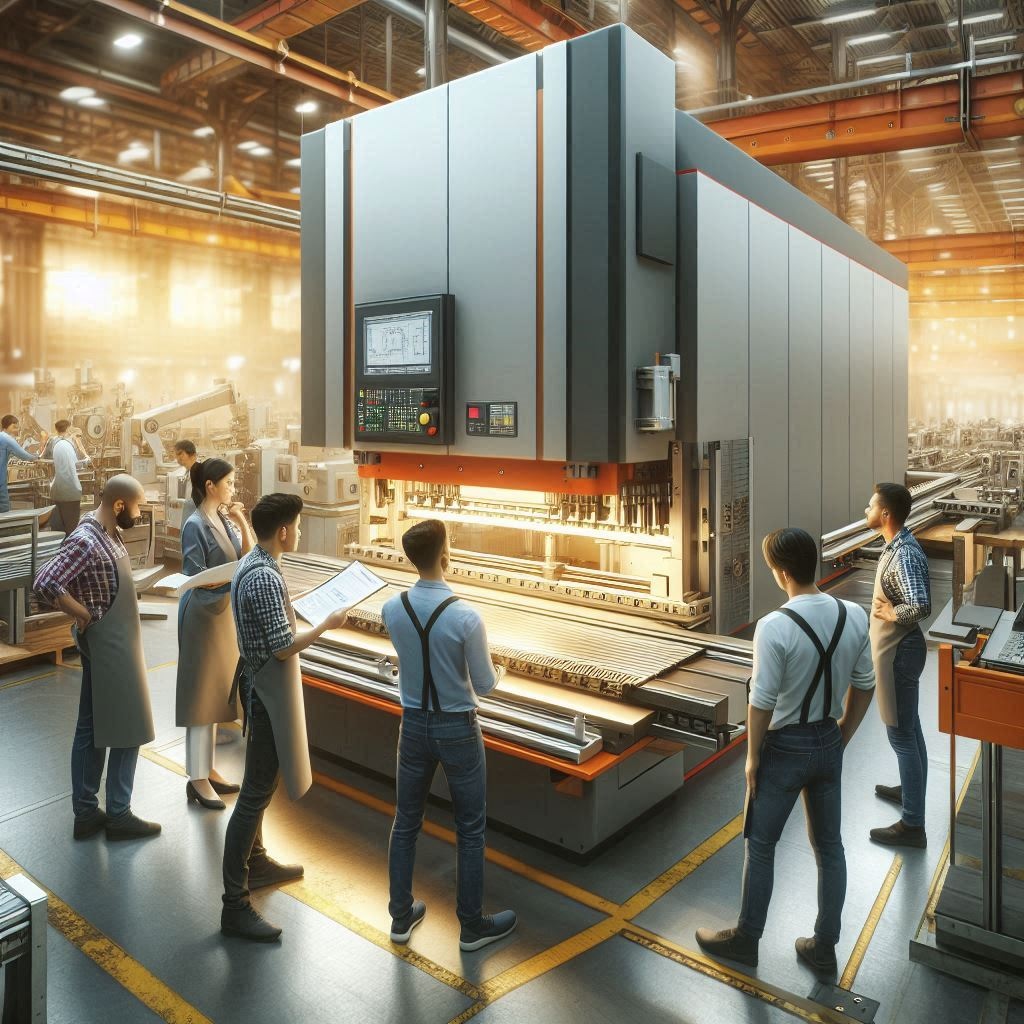

When searching for an NC press brake manufacturer in India, you want a company that will provide you with bending solutions that are accurate, efficient, and that will provide quality results for years to come. A good manufacturer of NC press brakes will supply you with the newest numerical control press brake technology, heavy construction, and hydraulic systems to provide repeatable and accurate bending. When considering an NC press brake manufacturer, they should have experience and the ability to create a reputable machine that is inline with custom manufacturing procedures. Additionally, consider the after sales service, availability of spare parts, reliability, and operator training which are also very important to increasing the productivity of the machine and minimizing down time. Because NC press brakes are manufactured to higher standards, the end result of using a trusted manufacturer based in India would provide you with a higher quality experience, better performance, and overall better direction for your fabrication business.

The Rise of NC Press Brake Manufacturers in India’s Metal Industry

The increase in NC press brake manufacturers in India’s metal sector indicates that the country is quickly advancing in its technology and areas of expertise in precision engineering. A few emerging industries, notably automotive, construction, and heavy fabrication experienced increasing demand leading to Indian manufacturers adopting numerical control systems, to produce bent parts with high rates of accuracy and efficiency. The new machines allow for high rates of repeatability, reduced set up time, and flexibility in complex bends. NC press brake manufacturers in India are setting new standards of quality and performance by melding innovation, durability, and cost-effectiveness, which thrusts India into the global response in the metal fabrication industry.

How NC Press Brake Machines Are Revolutionizing the Indian Metalworking Industry

NC press brake machines are changing the Indian metal-working industry with new levels of precision, efficiency, and automation in sheet-metal bending processes. NC press brake machines utilize numerical control technology, to produce accurate bends with uniformity, while significantly reducing manual errors and set-up time. The start-up of Indian manufacturers is integrating innovative hydraulic systems, programmable configurations, and digital controls to elevate speeds of production and value add in quality. Consequently, metal fabrication businesses are able to execute more intricate designs, while achieving higher overall productivity. This new technology is advancing the technical capabilities of Indian industries to meet aspects of global standards and building completeness in twenty-first century metal manufacturing.

Conclusion

To summarize, NC Press Brake India will provide a new level of accuracy and efficiency to the metalworking sector. The emphasis on technology, durability, and simplicity of use offered via automation is changing metal fabrication across all countries. If you consider a manufacturer that has been in business for a while in India, you are also investing in equipment that has demonstrated accuracy, dependability, and productivity.