If you’re still using traditional metal flooring in your industrial facility, you’re already behind. FRP Gratings India is leading a silent revolution in industrial safety, infrastructure, and performance—offering a solution that’s lightweight, corrosion-proof, and built for extreme environments. Fiberglass Reinforced Plastic gratings are used in several sectors from chemical plants to marine docks. Whether you are a manufacturer or contractor, or infrastructure builder, you need FRP gratings on the construction site for providing safety environment for industrial or construction workers.

What Are FRP Gratings and Why Are They Booming in India?

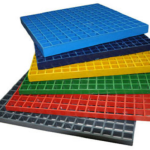

FRP Gratings India is a high-quality product, usually molded and fiberglass panels manufactured by bonding glass fabrics with resins to develop strong, non-corrosive, slip-resistant gratings. FRP Gratings do not rust, do not conduct electricity, require very low maintenance, and can be made in a variety of shapes and sizes within limits to suit the needs of many industries experiencing moisture, chemical and electrical hazards and not need frequent maintenance spells when operating in industrial sector or slippery environment.

Why FRP Gratings India Outperform Traditional Metal Gratings

Let’s face it—traditional steel gratings are riddled with problems: they rust in harsh environments, are heavy and labor-intensive to install, and present significant electrical hazards. It’s certainly a safety risk and a maintenance headache that most industries cannot afford! Here is where FRP Gratings India really shine. FRP Gratings are an incredible and innovative fiberglass alternative that is completely corrosion resistant, which makes them great for the chemical industry, marine docks, or almost any wastewater facility. FRP materials are light weight, are strong and durable. They are versatile hence finds application in wide range of industries that require slip resistant surface, non-conductive environments. For this reason, they are seen commonly used on electrical or telecom-related installations.

While also requiring virtually zero maintenance, you can easily eliminate costly upkeep. FRP Gratings are not only the safe choice, but also an environmentally conscious long-term decision.

Where FRP Gratings India Are Making an Impact

FRP Gratings in India have evolved farós today to play an essential role in critical operations across industries. In the chemical and petrochemical industries, FRP Grating stand against corrosive chemicals. Water and wastewater treatment facilities benefit from the rust-free properties of FRP Grating being in a constantly moist environment. their lightweight but durable construction makes them an ideal option for marine and offshore applications such as decks, docks, and ramps. In electrical substations and power facilities the non-conductive properties of FRP provides an additional level of safety commanded safety from electrical hazards. engineers and designers incorporate FRP Gratings into food and beverage applications for their hygienic, anti-slip surface and cleanability properties. municipalities and public infrastructure projects rely upon FRP Grating for long-lasting stair treads, drainage covers and pedestrian bridges. FRP Gratings India have been engineered and produced for use in the demanding environments where metal is typically the choice of material. FRP Gratings is quickly becoming the leader in providing safer smarter industrial flooring applications.

Choosing the Right FRP Gratings Manufacturer in India

The requirements of FRP gratings might be industry specific. Hence selection of the right FRP Gratings Manufacturer who understand the basic requirements, knows the specification and FRP grading standards is essential. For this reason, we must check the official website of the FRP grating manufacturer, check out their ISO certification, relevant experience in manufacturing FRP products and feedback of their customers before making any decision. They will also have an unmatched level of customization available, including different panel sizes, resin types, and load capacity requirements for consistent use. Points like proven years in the industry, a solid reputation with many happy clients, and proof of previous installations, will demonstrate trustworthiness. In the same fashion, responsive technical support, responsible after sales services, and weaving production to cater to both smaller and larger jobs are equally important. You can be reassured that your gratings will be precision engineered to suit your application regardless of how complex it may be, if you are teaming with a credible manufacturer.

FRP Gratings India: Built for Harsh Conditions, Designed for Long-Term Performance

Industries no longer have to deal with high maintenance and corrosion prone flooring. FRP Gratings are built to withstand the toughest industrial conditions found throughout India, whether that be the monsoon-soaked coastal zones, the high-temperature interiors of chemical plants, or the safety-sensitive flooring of electrical substations. FRP gratings offer unparalleled strength, with built-in safety features and zero maintenance compared to other conventional flooring options, and are not only a product, they are a performance enhancement.

Conclusion: Why FRP Gratings India Should Be Your Next Investment

If you are committed to improving safety, reducing costs associated with maintenance and changes, and future-proofing your facility, FRP Gratings India will be your next step. With an increasing demand and better technology and more availability from larger, reputable manufacturers, there has never been a better time to make the change. Your floorings should be an industry standard, and with FRP Gratings India, you can make this happen.