Introduction

Industrial practices require constant delivery of gases and liquids because it determines process operational success. The ball valve proves to be one of the most dependable choices when it comes to fluid control operations. Using ball valves transforms flawless fluid flow control in the industrial sector. Still, selecting the correct ball valve manufacturer is equally crucial to guarantee the product’s effectiveness and lifetime. We shall discuss the function of a ball valve maker, their significance, and the reasons Sagarvalve distinguishes itself in the sector on this blog.

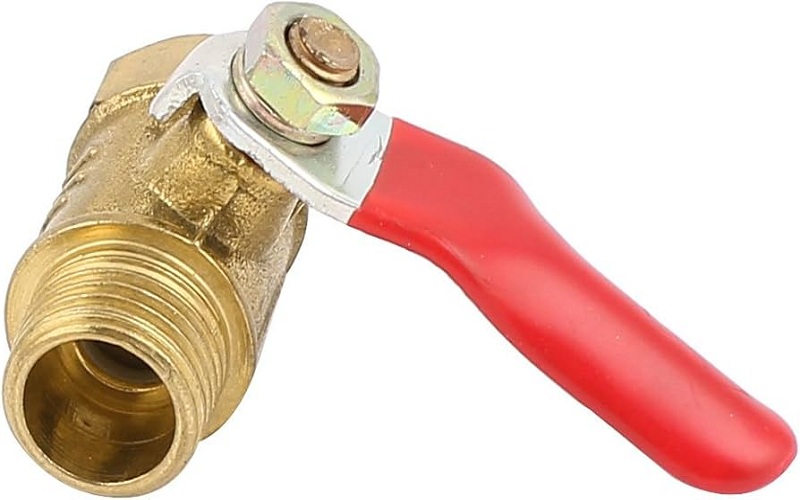

What is a Ball Valve?

The ball valve operates by using a hollow perforated moving ball which controls fluid and gaseous passage through it. Because it shows consistent performance coupled with great durability and simple operations, the ball valve finds several uses in industrial, commercial, and household sectors. Design and supply of premium ball valves capable of withstanding high pressure and temperature is the main responsibility of a ball valve manufacturer.

Role of a Ball Valve Manufacturer

The successful output of valves appropriate for multiple industries like oil and gas and chemical processing and water treatment functions because of a ball valve manufacturer.

Key Responsibilities of a Ball Valve Manufacturer:

- Design and Engineering: Creating accurate designs and high-quality prototypes.

- Material Selection: Using durable materials such as stainless steel, brass, or PVC.

- Testing and Quality Control: Quality checks through testing verify that the ball valves remain functional under high-pressure and harsh temperature conditions.

- Customization: Offering custom-made ball valves as per client requirements.

- Timely Delivery: Speedy delivery must be maintained to prevent industrial operational stoppages.

Types of Ball Valves Offered by Sagarvalve

As a reputed ball valve manufacturer, Sagarvalve offers a wide range of ball valves tailored to meet industrial standards. The industry uses several ball valve types among which three main variants stand out.

- Floating Ball Valve

The valve structure incorporates a ball which rises through the valve body thus delivering both reduced friction and total flow control. Operating under low-pressure conditions constitutes the main application for this type of ball valve.

- Trunnion Mounted Ball Valve

The trunnion mounted ball valve incorporates extra mechanical attachments that enable it to handle pressure-intensive and expansive pipe frameworks.

- Forged Steel Ball Valve

Forged steel serves as the production material in these ball valves because it delivers durability along with corrosion resistance properties.

- Two-Piece Ball Valve

A two-piece ball valve contains body sections which connect through bolted assembly. Such valves provide simple maintenance as well as quick cleaning steps and straightforward repairs.

- Three-Piece Ball Valve

The chemical and food production sectors employ three-piece ball valves as their standard device. You can easily separate the valve for both cleaning and maintenance operations.

Why Choose Sagarvalve as Your Ball Valve Manufacturer?

Quality, durability, and efficiency depend on choosing the proper ball valve manufacturer. The industry trusts Sagarvalve to make high-performance ball valves. These are the fundamental elements that determine Sagarvalve as a preferred manufacturer choice:

- Superior Quality Products

Sagarvalve produces ball valves through the utilisation of top-grade materials which enable the valves to function at extreme operating conditions.

- Customization Options

The business needs among different industries drive Sagarvalve to deliver specialised ball valve products. The company makes custom ball valves which fulfil demands of particular industrial applications.

- Competitive Pricing

Being a reputed ball valve manufacturer, Sagarvalve ensures that their products are reasonably priced without compromising on quality.

- Global Reach

Sagarvalve serves customers through international exports of its ball valve products which makes them a trusted industrial manufacturer.

- Exceptional Customer Service

Sagarvalve earns industry preference through its continuous customer support along with its technical assistance service.

Industries That Use Ball Valves

- Oil and Gas Industry

Ball valves serve as a common choice within the oil and gas industry to control pipelines as well as operate gas processing equipment and regulate pressure levels.

- Water Treatment Plants

Ball valves inside water treatment sites enable operators to control clean and wastewater through their facilities.

- Chemical Industry

The characteristics of ball valves make them suitable for managing dangerous substances and maintaining steady industrial operations.

- Food and Beverage Industry

Sanitary ball valves serve the food industry by preserving cleanliness throughout the flow management of liquid food materials.

Factors to Consider While Choosing a Ball Valve Manufacturer

- Material Quality

Always ensure that the ball valve manufacturer uses high-quality raw materials to enhance product durability.

- Product Certification

Check for manufacturers Sagarvalve because they provide ball valves which received certification through international standard tests.

- Customization Facility

A good ball valve manufacturer must provide customization options according to industrial requirements.

- After-Sales Service

After-sales service needs to be reliable because it ensures maintenance as well as technical assistance for valve systems.

- Competitive Pricing

Check the prices between ballistic manufacturers so you can acquire premium ball valves at their lowest cost points.

Conclusion

Choosing the right ball valve manufacturer is essential for industrial growth and operational efficiency. Sagarvalve established itself as the industry leader that provides durable customised ball valves which support various industrial sectors. Their commitment to high international standards of quality and service has established a world-renowned reputation for Sagarvalve. If you are looking for a trusted ball valve manufacturer, Sagarvalve is your go-to solution.

Call to Action

Looking for high-quality and affordable ball valves? Sagarvalve is the best ball valve manufacturer you can rely on. Contact us today to get customized solutions for your industrial needs.

FAQ

- What is a ball valve used for?

This regulatory tool controls water treatment facilities and chemical industrial activities as well as liquid and gaseous material flow over pipelines within the oil and gas industry.

- Why should I choose Sagarvalve as my ball valve manufacturer?

Sagarvalve produces durable ball valves which are customizable according to specific requirements and marketed at competitive industrial rates for maximum industrial use.

- What materials are used in making ball valves?

Stainless steel along with forged steel and PVC and brass serve as commonly used materials because they provide both high resistance to corrosion and durability.

- Can I get a customized ball valve from Sagarvalve?

Yes, The Company provides customised ball valves to address different industrial specifications.

- Does Sagarvalve provide international delivery?

The ball valve manufacturing company Sagarvalve provides worldwide export service together with speedy delivery and superior client support.